OPTIPA SYSTEM FOR MACHINES FOR THE PRODUCTION AND REFINING OF “CONTINUOUS WEBS“

One of the main areas of application of OPTIPA systems are machines for the production or finishing of continuous webs. These machines produce an endless strip of product that is usually either wound into rolls or processed on cutting machines into sheets of different dimensions.

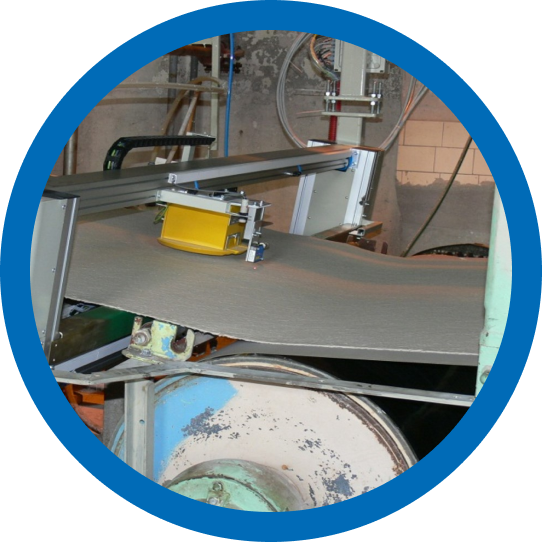

A specific application of the OPTIPA system is the plate making machine on conveyors.

The basic functions of the OPTIPA system for all of these machines include the measurement or control of selected quality parameters – moisture, weight or thickness – either of the whole product or, if possible, selectively of individual layers.

Měřené materiály

paper

cardboard

corrugated cardboard

foils

laminated foils

application of 1 or more layers (lacquer, adhesives)

floor coverings, PVC, rubber coverings

non-woven fabrics

roofing boards, roofing materials and foils

many more - consult with us

Using our systems, you can:

significantly reduce raw material and energy costs of production by hundreds of thousands to millions of CZK per year

increase machine productivity by up to 10%

to contribute to the improvement of product quality by reducing the unevenness of their quality parameters

make operators' work more efficient thanks to automatic machine control

increase employee awareness of production parameters using information system functions

areas of application of the OPTIPA system

Typical areas of application of OPTIPA systems including possible measured/controlled parameters are:

Paper machines

- paper moisture measurement / control

- paper basis weight measurement / regulation

- paper thickness measurement / regulation

Finishing machines (impregnation, varnishing, laminating, etc.)

- moisture measurement/control of the final product

- measurement/control of the basis weight of the final product

- measurement/control of the basis weight of the coating (adhesive, varnish, PE, etc.)

- measurement/control of the thickness of the final product

- measurement/control of coating thickness (adhesive, varnish, PE, etc.)

Cardboard machines

- moisture measurement / control of cardboard

- measurement / regulation of cardboard basis weight

- cardboard thickness measurement / regulation

Machines for the production of corrugated board

- measurement/control of the moisture content of the final product

- measurement/control of the moisture content of individual corrugated board layers

- measurement/control of the adhesive application basis weight

Machines for the production of roofing boards, roofing materials and foils

- product moisture measurement/control

- measurement/control of the product’s basis weight

- product thickness measurement/control

Machines for production of PVC floor coverings, rubber coverings

- measurement/control of the product’s basis weight

- product thickness measurement/control

Machines for the production of flat films, foils, laminated films (laminated)

- measurement/control of film basis weight

- foil thickness measurement/control

Machines for the production of nonwovens, felts

- nonwoven fabric moisture measurement/control

- measurement/control of the weight of the nonwoven fabric

This list does not represent the final list of OPTIPA deployment options !!! Please ask us about the possibility of deploying the OPTIPA system on an application not listed here !

Description of the OPTIPA system

The OPTIPA system is designed as a modular system, which allows the delivery of individual modules separately.

The three basic modules are:

Measurement of endless belt parameters

Visualization of the process

Process control

Measurement of endless belt parameters

This basic module consists of several key components, which are:

1) special instruments for measuring the qualitative properties of the produced strip, i.e.

moisture measurement

- sensors based on the infrared absorption principle

- microwave absorption sensors

basis weight measurement

(of the whole product or just the coating, coating or impregnant)

- beta and gamma absorption sensors

- infrared absorption sensors

thickness measurement

(of the whole product or just the coating, coating or impregnant)

- beta and gamma absorption sensors

- infrared absorption sensors

- sensors based on the optical measurement principle (triangulation principle)

- eddy current sensors

2) primary evaluation units

Special measuring instruments.

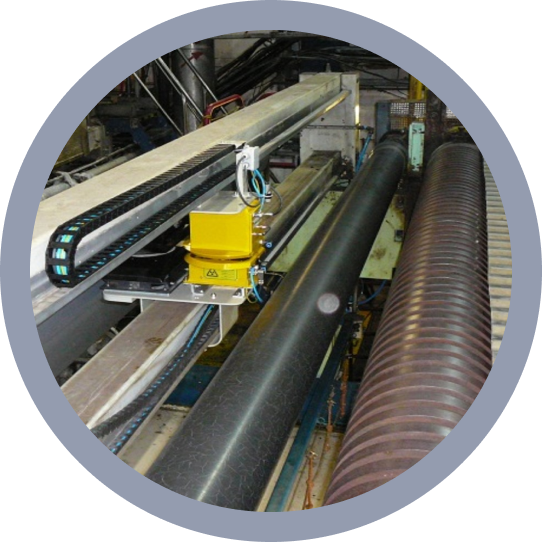

3) measuring frames

For mounting special measuring instruments (traversing C-frames, O-frames or I-frames or frames/holders for fixed position measurements).

The above components are connected to a switchboard containing a PLC with customized OPTIPA application software. The PLC’s task is to sense and evaluate signals from the system components used (i.e. measuring instruments, photocells, magnetic end position sensors, etc.) and to perform basic control operations (control of the traversing frame movement, control of the radioactive instrument aperture, etc.). Possible light or sound signalling elements and digital indicating instruments may also be included in this module.

Visualization of the process

The software for this module can be located in the PAC for most applications (see measuring frame). Industrial/standard monitors with keyboard and mouse are used as communication means, all connected to a PC (networked to the PAC), equipped only with a standard browser.

For large scale communication applications, an industrial PC with SCADA visualization software Citect (including HW key) is used. If desired, a printer can be connected to the PC. The industrial PC communicates with the PAC via OPC. The application software OPTIPA runs in the Citect environment.

Both versions of the visualization can include features such as:

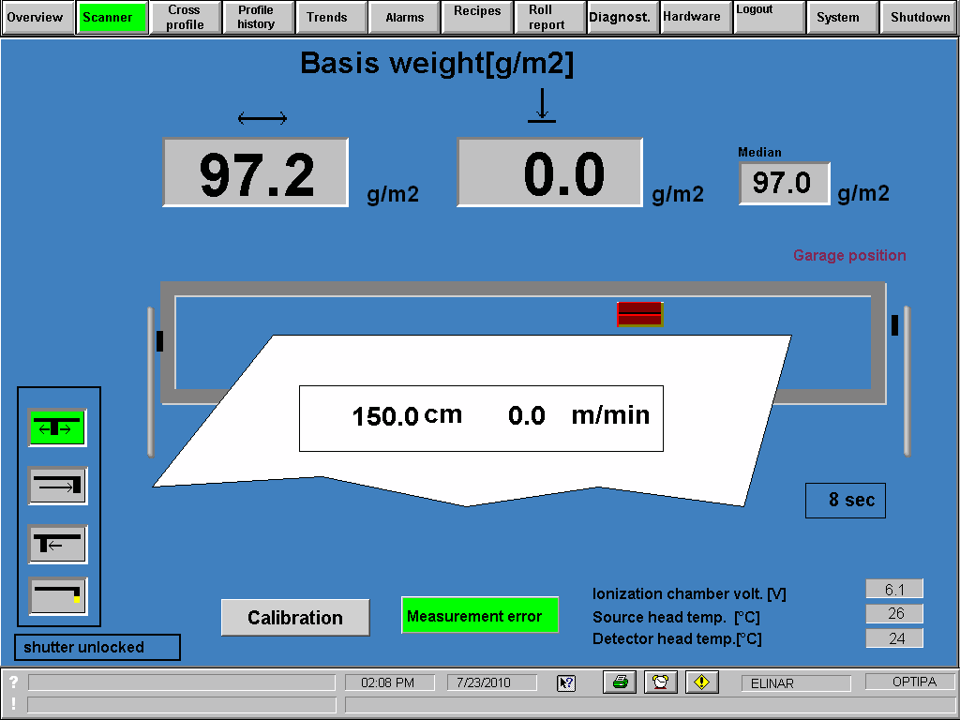

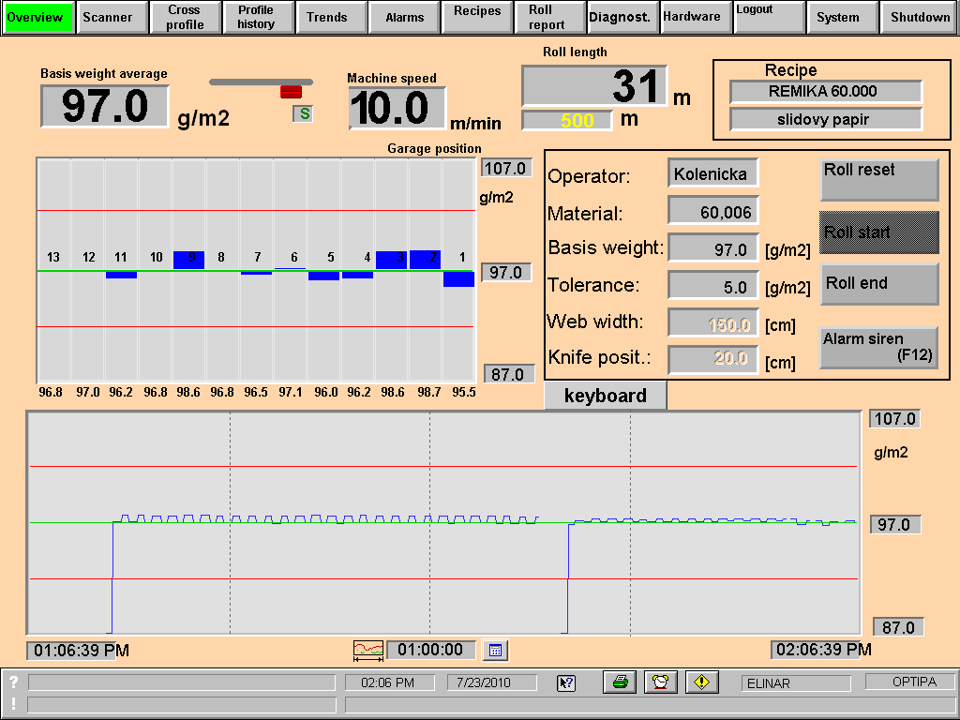

clear display of the production technology including instantaneous values of the measured quantities (moisture and/or specific basis weight and/or thickness) and, where applicable, other operating quantities such as temperatures, flow rates, speeds, revolutions, etc.

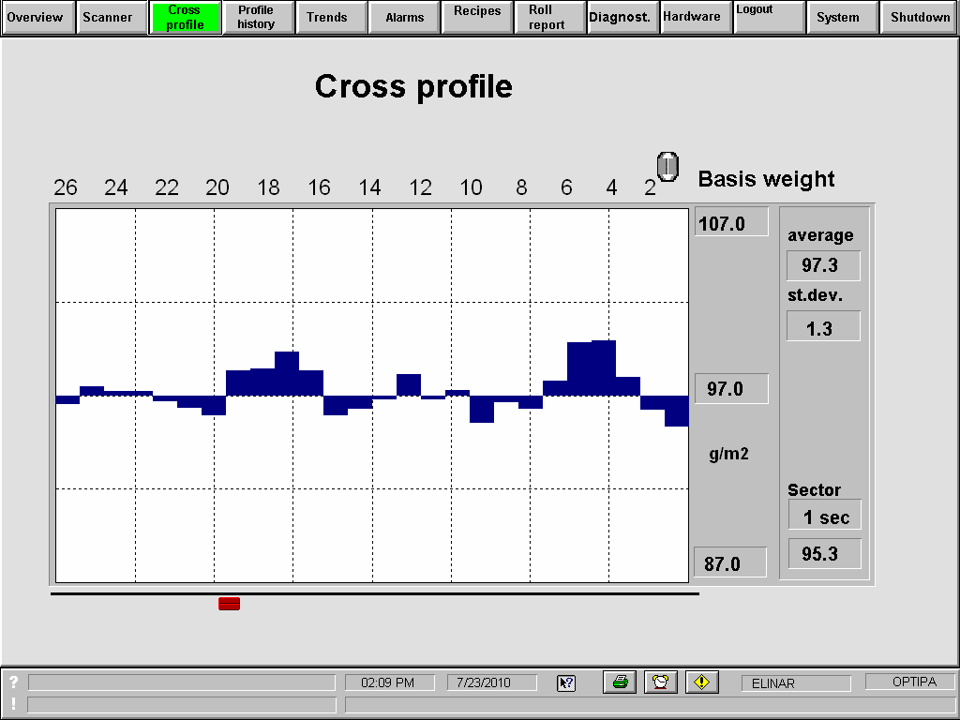

display of transverse profiles of measured quantities

schematic representation of the position of the frame and elements for its control

calculation and display of the required statistics of the measured variables per crossing (averages, standard deviations, medians, etc.)

automatic continuous trend storage of measured and calculated variables within the Citect software with archiving times of up to several years

sophisticated trend display of selected variables with a wide range of settings (displayed variables, trend length, trend end date and time, display limits, etc.)

automatic export of trends in *.csv format to a user-defined location (e.g. to a company server)

processing of production, shift and role reports and their display/printing/export to a specified location (e.g. to a company server)

display of current and historical alarms indicating production interruptions or the occurrence of out-of-limit conditions and other critical situations

This list of possible functions of the OPTIPA application software is not definitive, the programming of the software always takes into account the requirements and needs of the customer. The OPTIPA application software can be modified or supplemented at any time if necessary.

Process control

This module represents the highest level of the superstructure. It is based on the inclusion of control functions in the OPTIPA application software localized in the PLC and in the industrial PC (Citect). Control of quality variables is possible not only in the longitudinal direction (i.e. in the production direction) but also in the transverse direction.

The control functions are designed and implemented according to the type of machine on which the OPTIPA system is to be implemented. In principle, the same elements (actuators) are used for control that were used for manual adjustment by the operator of the respective machine before the implementation of the automatic control system.

Example

The OPTIPA system for a paper or board machine usually includes the following basic control functions:

- Controlling the basis weight by the flow of a dense substance

- Basis weight control by machine speed

- Moisture control by steam pressure

- Control of ash content by kaolin flow

- Efflux control

Optionally, the OPTIPA system can be supplemented with a higher level of control algorithms:

- Optimization of the desired values (basis weight, moisture content)

- Coordinated change of machine speed

- Maximising production

- Automatic change of type

- Cross profile control